FLUID-LINER®

high efficient reagent-free technology of service of liquid media in pipelines and apparatus, providing two important improvements:

-

removal of all kinds of deposits

-

increase of pumping-over velocity of media

FLUID-LINER® technology has been developed in Germany and providing by group of companies SUTRA-IFT since 2001.

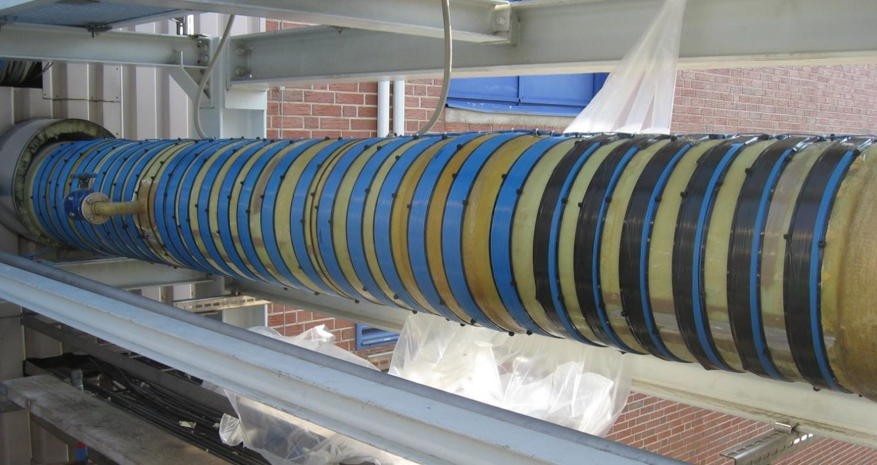

The set of equipment typically consists of two parts:

|

|

|

|

Electrical ecable, |

Electric cabinet |

Equipment generates alternate electromagnetic field modulated with a special algorithm.

This field, penetrated into media through the pipeline wall, establish two physical effects:

|

1) Demolition of crystallization clusters, |

2) Homogenization of suspended solids |

|

|

|

|

|

FLUID-LINER® technology is applied in different industrial areas

REMOVAL OF DEPOSITS

Depositing of salts and organic substances is well-known and important problem in the course of operation of liquid media pipelines, heat exchangers and other apparatus. It causes:

-

narrowing of pipeline section, down to complete blockage

-

reducing of exchangers efficiency

-

excessive load to pumping equipment

-

corrosion of pipes and apparatus

examples of blockage

|

|

Depositing causes forced wear of equipment, provokes often breakpoints for cleaning and repair of pipelines, increases consumption of expensive chemical reagents.

As a result, profitability and output of products are decreased.

FLUID-LINER® allows to remove or significant reduce problems related to deposits in pipelines, as well as to reach substantial economic benefit due to the dramatic reduction of losses and expanses

-

avoiding of overconsumption of heat energy (at heat exchangers)

-

keeping of production capacity of a shop (division), or increase of output

-

extension of lifetime and overhauls period of pumps, exchangers and valves

-

reduction of expenses for repair and recovery works

examples of reached effect

|

Langenbram, Germany Wastewater treatment plant

2006 2013 |

Gifhorn, Germany Stripping column (packing)

2008 2009 |

Augsburg, Germany Paper factory

2008 2009 |

|

(images show condition of service object before and after applying of FLUID-LINER®) |

||

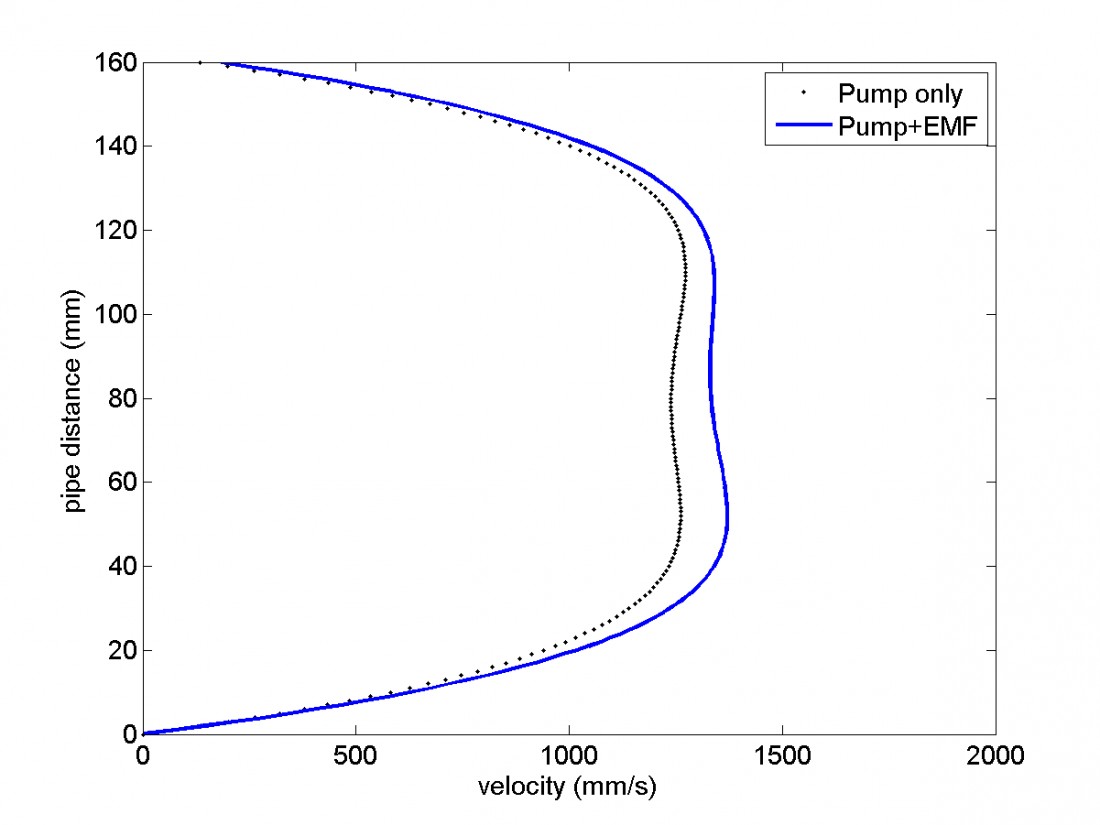

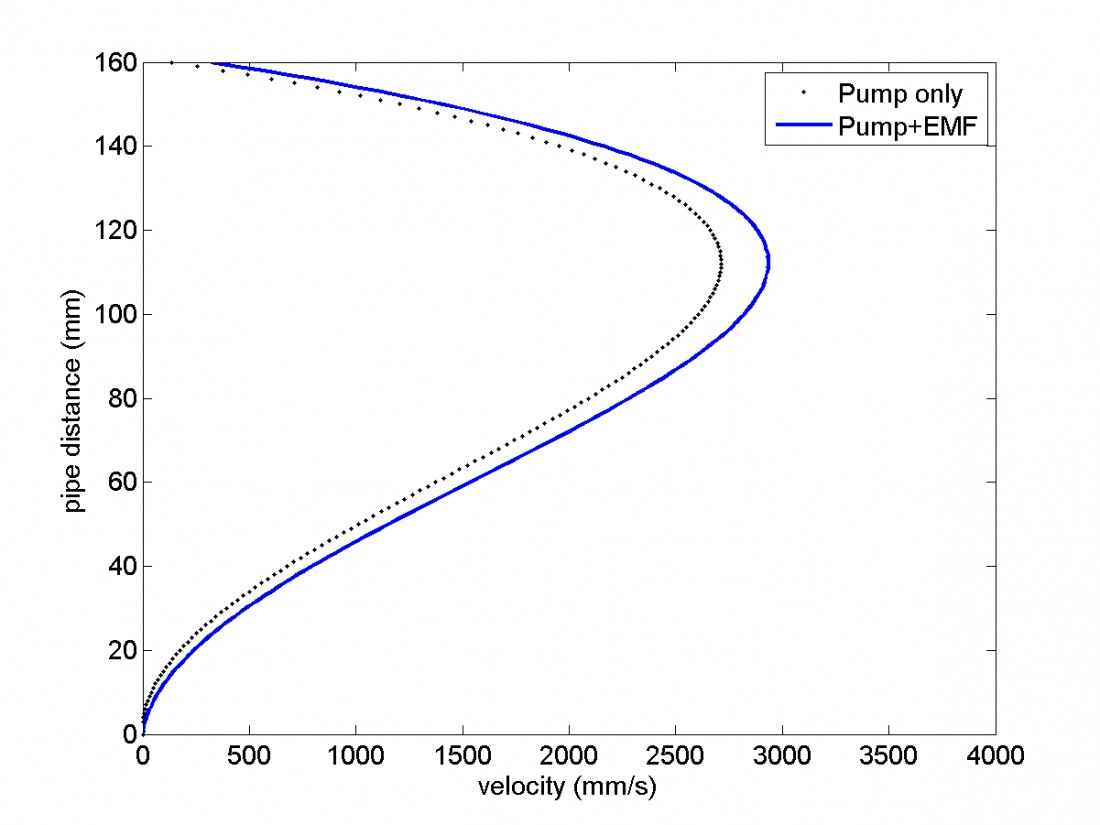

INCREASE OF PUMPING-OVER VELOCITY OF MEDIA

FLUID-LINER® provides increase of velocity of flowing of heterogenic operation media (pulp, suspension, sand-water mix) in pipeline, in average at ~10%.

typical velocity profiles of pulp flow

|

|

|

|

sand-water mix |

thin suspension |

|

(grey line – without FLUID-LINER®, blue line – with FLUID-LINER®) |

|

This effect is certified with different media in pilot and industrial operational cases:

|

|

|

|

|

|

Pilot test: pumping-over of liquid concrete |

Dredging with supply of sand-water mix at 12 km distance. |

||

FLUID-LINER® allows to reach substantial economic benefit with transportation of heterogenic media

-

increase of velocity of operational media, or

-

reduction of load and energy consumption of pumping equipment

.jpg)

.jpg)